- Home

- All Posts

- Slitting System

- Choosing Slitting Method for Slitting Equipment

Blog

Choosing Slitting Method for Slitting Equipment

Before you are ready to purchasing a slitting equipment, it is necessary to choose the right slitting method for your material. Choosing the wrong slitting methods will cause stretched material, frayed edges, or other issues which are unwanted for the next step of the production process. There are many important factors in choosing the proper slitter method such as the type and thickness of the materials being processed. Generally slitter equipment uses three kinds of slitting methods to slit material into narrow rolls: razor slitting, shear slitting and score slitting.

Razor slitting method

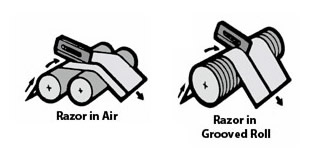

As the most economical method, the razor blades are very simple and easy to setup, frequently used to slit various materials both woven and non-wovens like plastics or films. The materials are unwound from the roll, passes over the razors, and slitted in the air or in a grooved roll, finally get re-wound onto the child cores.

As the most economical method, the razor blades are very simple and easy to setup, frequently used to slit various materials both woven and non-wovens like plastics or films. The materials are unwound from the roll, passes over the razors, and slitted in the air or in a grooved roll, finally get re-wound onto the child cores.

Nevertheless, razor method is hard to cut rigid, heavy or abrasive materials especially in some high-speed slitting equipments. Wrong razor blades may generate enough heat to melt the film or creat a bead which is detrimental to achieving good winding. Besides, although the razor blades are of low cost, they need to be frequently changed to ensure a good quality slit edge.

Score slitting method

Score slitting, also referred to as “crush slitting”, is the oldest form of slitting and the first employed on slitting equipments. A male knife runs against a hardened anvil shaft and crush the material to sever one part from the other. This method has advantage of quick setup, and suitable to slit many materials including non-wovens, foams, and pressure-sensitive adhesives because it can create a dry and non-sticky edge.

Score slitting, also referred to as “crush slitting”, is the oldest form of slitting and the first employed on slitting equipments. A male knife runs against a hardened anvil shaft and crush the material to sever one part from the other. This method has advantage of quick setup, and suitable to slit many materials including non-wovens, foams, and pressure-sensitive adhesives because it can create a dry and non-sticky edge.

When the score slitting method is applied to slit paper material, it creates dust accumulation and cause running trouble of equipment. Also, if a defect appears when slitting plastic film and sheet, this can create film stretching or deformities. It may cause cracking when the score knife is used on hard plastic.

Shear slitting method

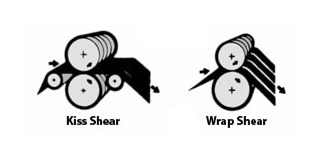

This slitting system has two rotary knives which are utilized to produce the same cutting effect as scissors through heavier materials such as paper, films, foils, laminates and other no-woven materials. This method can provide not only excellent cutting but also accurate slitting widths and close tolerances, they stay sharp longer than razor blades.

This slitting system has two rotary knives which are utilized to produce the same cutting effect as scissors through heavier materials such as paper, films, foils, laminates and other no-woven materials. This method can provide not only excellent cutting but also accurate slitting widths and close tolerances, they stay sharp longer than razor blades.

The setup for shear knife is extremely precise and requires achieving an ideal angle at the junction of the blades. It need to take longer time to position, although the setting time can be reduced by using an automatic knife-positioning system.

Various applicaton has different goals and uses different machinery, materials, and processes, LEAP has enough designing and manufacturing experience to help you choose the best slitting methods for your slitting equipment.

About Lvjie

Serch

Recent Posts

-

Overview of UHMWPE Separato... September 20, 2024

-

Overview of PVC Slitter Rew... July 2, 2024

-

Overview of Pre-coated Film... April 25, 2024

-

Overview of stretch film sl... March 11, 2024

-

Application of BOPP Tape Sl... November 29, 2023

Categories

- All Posts (28)

- Others (1)

- Unwinding Technology (3)

- Rewinding Technology (7)

- Slitting System (18)

- Control System (4)

Contact Info

Xiongzhou Street, Liuhe District, Nanjing City, 211511, China

Phone: 86 025 86555699Email: info@film-slitter.com

Recent Posts

-

Overview of UHMWPE Separato... September 20, 2024

-

Overview of PVC Slitter Rew... July 2, 2024

-

Overview of Pre-coated Film... April 25, 2024

-

Overview of stretch film sl... March 11, 2024

-

Application of BOPP Tape Sl... November 29, 2023