- Home

- All Posts

- Unwinding Technology

- Types of Unwinding Solution

Blog

Types of Unwinding Solution

The unwinding process is responsible for feeding of material into machine, it must be capable of bearing weights of rolls and work precisely with your slitter rewinder machines. The type of unwind solution is usually determined by the size and weight specifications of the material that the machine is designed to handle.

Shafted unwind and shaftless unwind

Shafted unwind is a typical and cost-effective unwinding stand, it can handle a variety of width rolls and offers high-level grip between shaft and core. Unfortunately, large-diameter unwinds generally require larger core shaft and core sizes to accommodate the weight of the roll, therefore machine operators have to deal with excessive shaft weights prior to setting the roll into the unwind. An alternative is the new lightweight carbon fiber shaft, which is less than half weight of the solid steel or pneumatic core shafts without any loss of roll weight capacity.

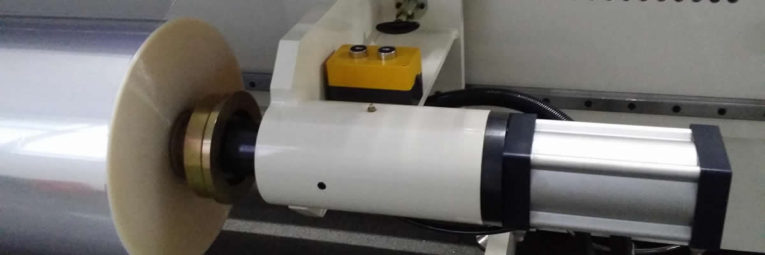

Shaftless unwinds avoid the need for the operator to handle shafts and result in less injury, most of the shaftless unwinder is fitted with roll lifting devices that position the roll prior to engaging the chucks to hold the roll. With the growth of the cost of employee injury, more and more factories are moving in the direction of shaftless unwinds with roller lift equipment. Besides, a new design of turret shaftless unwind can minimize changeover times because the new roll can be loaded into stand while the other roll is unwinding.

Integrated unwind and separated unwind

As an independent module mounted on the main machinery frame, the integrated unwinder consists of plates on two sides, a connecting cross bar and two safety bearings which are used to fit with unwinding shaft. Left and right unwind frame can transverse move singly, open the lock bolt and manually pushed to the proper working position, and then you can lock again. Hydraulic lifting structure can make the unwind automatically. Integrated unwinding station is designed for a wide variety of mother rolls with standard diameter.

The separate unwinder is an independent module connected to the main machine frame through a walk-on bridge. It consists of plates on two side, a connecting cross bar and two safety bearings to receive the unwinding shaft. The unwinding shafts are driven through AC servo-motors and generally have cantilevered design to ease loading operations. The running speed can be automatically adjusted along with diameter decreasing. Also available as forck type for mother roll pick-up from floor. Separated unwinding station is suitable for larger mother roll diameter.

Braked unwind and driven unwind

Braked unwind also known as passive unwinder, utilizes a brake on the unwind roll resists the winder’s torque and creates tension in the web material. Because diameters of roll material increasingly change, the unwinding brake should compensate to keep constant web tension. Excessive tension may cause material to stretch or even break, unwind brake must gradually reduce torque when the roll diameter gets smaller. A load cell transmits the inspected tension signal to PLC which gives orders to tension amplifier after calculation through PID and comparison, further to gradually reduce input electrical current to magnetic powder brake, which reduces torque to maintaining the proper film tension level. Generally speaking, this type of unwinding method is proper for narrow-width small slitting machines and not proper for tension-sensitive materials.

Driven unwind also known as active unwinder, is often applied for thin, extensible films. The master roller is driven by a motor, and offers unwind solutions for a wide range of roll diameters and roll weights. The unwind stand must have enough rigidity, strength and weight to prevent deformation and vibration. Also exceptional tension control should be built into unwind systems, the tension of the film is controlled by a dancer roller located after the unwind, and the position of dancer roller should be at the middle of its range while running. a potentiometer monitors the position of dancer roller, once the machinery is started with the dancer roller at a position other than the midrange, the speed of the unwind drive motor will be adjusted via a signal feed-back from the dancer arm and guarantee the dancer roller correctly positioned. The tension on the web is equal to the loading in the dancer.

Each unwinding station should be based on material properties including speed, thickness, width, size of mother rolls, and how the roll will be used in the web process all need to be considered when engineering an unwind. LEAP could equipped our slitter rewinder machines with right unwinding solution according to specific requirements.

About Lvjie

1 Comment

Leave a Comment

Serch

Recent Posts

-

Overview of UHMWPE Separato... September 20, 2024

-

Overview of PVC Slitter Rew... July 2, 2024

-

Overview of Pre-coated Film... April 25, 2024

-

Overview of stretch film sl... March 11, 2024

-

Application of BOPP Tape Sl... November 29, 2023

Categories

- All Posts (28)

- Others (1)

- Unwinding Technology (3)

- Rewinding Technology (7)

- Slitting System (18)

- Control System (4)

Contact Info

Xiongzhou Street, Liuhe District, Nanjing City, 211511, China

Phone: 86 025 86555699Email: info@film-slitter.com

Recent Posts

-

Overview of UHMWPE Separato... September 20, 2024

-

Overview of PVC Slitter Rew... July 2, 2024

-

Overview of Pre-coated Film... April 25, 2024

-

Overview of stretch film sl... March 11, 2024

-

Application of BOPP Tape Sl... November 29, 2023

For the example above, the possible unwind directions would be 1 or 2 (if sealant in) or 5 or 6 (if sealant out).